NORMA Group is a world leader in the supply of engineered joining technologies. Our clamps, connectors and fluid systems secure the quality, reliability and performance when critical applications require technologically advanced connections to maintain operational integrity and safety.

High-grade materials, state-of-the-art development methods, advanced know-how and exact processing are the essential ingredients of every product. This, combined with our ISO certifications and quality assurance programs, makes NORMA a global leader of superior clamping and connecting technologies solutions.

Customers the world over rely on NORMA for innovative products and solutions that provide uncompromising connections, outstanding performance, unmatched reliability and long service life. Our application-specific solutions create value for our customers and provide them with competitive advantage.

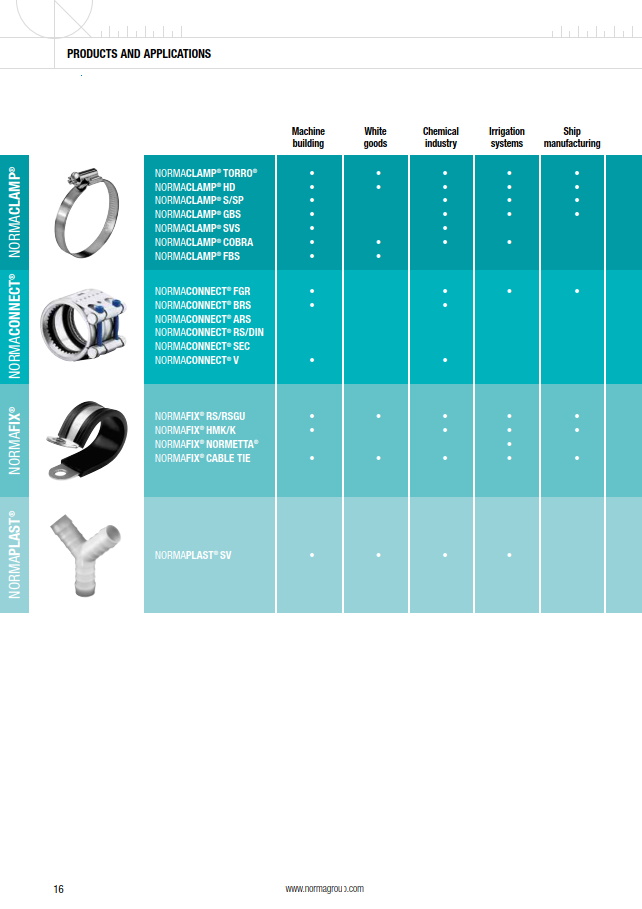

Wherever in the world you are, and whenever you need superior clamping products, there is always one of our products for your first choice. For over sixty years we have been dedicated to working closely with suppliers and customers to develop products that boast outstanding functional performance. We enjoy support from dedicated employees, all of whom have the goal of exceeding the expectations that customers bring us on a daily basis. Hose clamps, pipe connections, retaining products or plastic products. Regardless of its use, every NORMA® brand product is designed, produced and delivered within the framework of a certified quality-management system, which is essential for achieving the innovative yet robust designs demanded by end-users.

For NORMA Group, quality is an all-embracing value, ranging from product design to delivery and beyond, to cover all aspects of the group’s activity including its service to customers. Regardless of the sector in which a NORMA® product is to be used, that product will be designed, produced and delivered within the framework of a TS 16949 certified quality-management system developed for the critical demands of the automotive industry. Within this context, Advanced Product Quality Planning (APQP) and associated quality tools such as Failure Mode and Effect Analysis (FMEA) are all fundamental to the development of reliable parts and error-proof production processes.